Sales

Rental

Repair

Anchors & Fastener Systems

Boise, ID 208-377-0158

Eugene, OR 541-342-3641

Idaho Falls, ID 208-522-7082

Medford, OR 541-779-0187

601

SIMPSON STRONG-TIE®

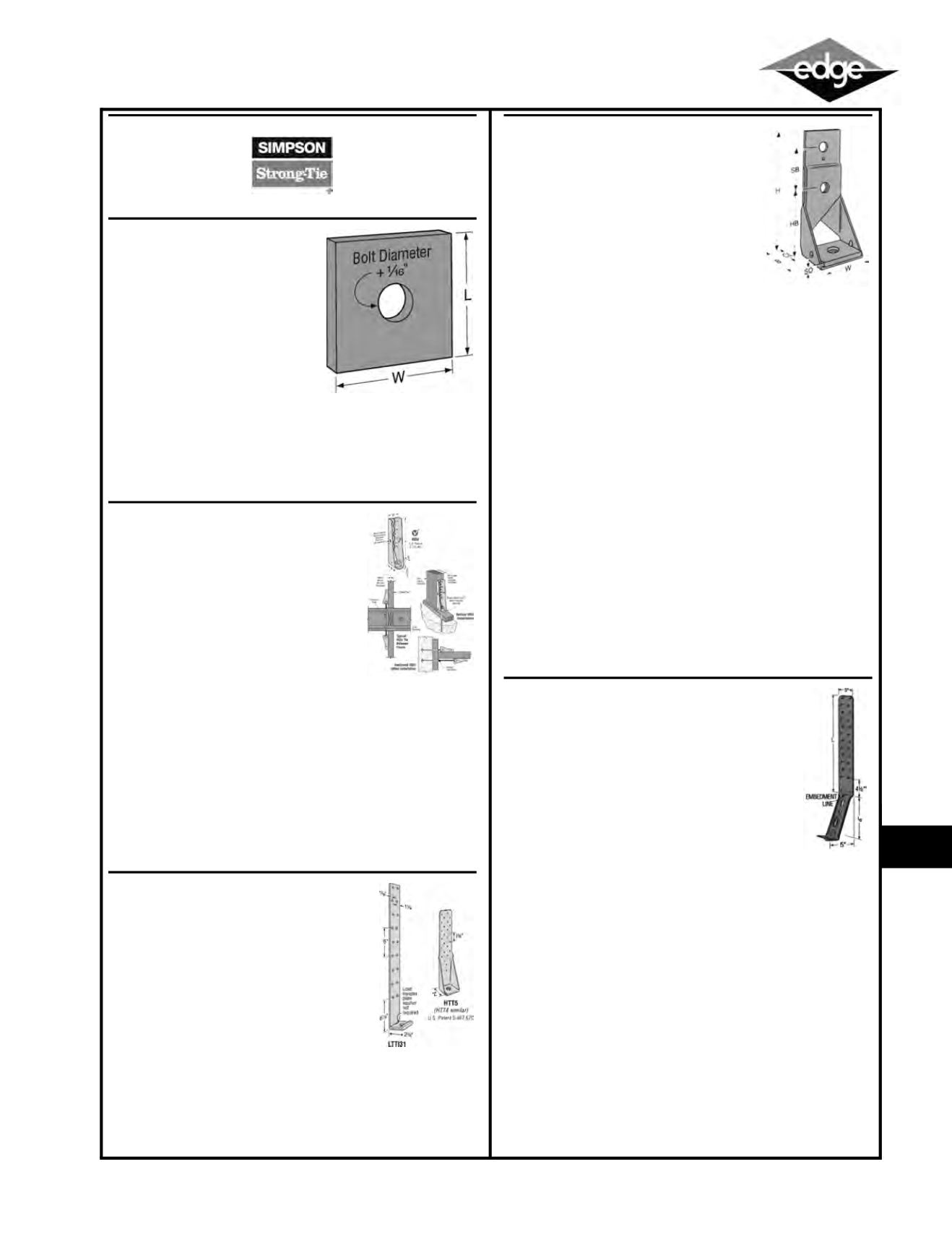

BP Bearing Plates

•

Bearing Plates give greater bearing

surface than standard cut washers,

and help distribute the load at

these critical connections

•

The BP 1/2 - 3 and BP 5/8 x 3 are

3” x 3” bearing plates that meet the

latest requirements of the IRC and

IBC; these plate washers are

available un-coated or with a HDG

coating

•

The BP5/8SKT uses SDS 1/4” x

1-1/2” screws to provide lateral resistance when 5/8” diameter sill

holes are over-drilled (screws are provided)

•

The shear capacity of the connection and the sill/anchor bolt shall

be determined by the Designer for each installation

•

Finish: BP5/8S - Galvanized; BP 7/8 - 2 - Zinc Plated; BP - None.

BP’s may be ordered in HDG

SIMPSON STRONG-TIE®

HDU Holdowns

•

HDU Holdowns are pre-deflected during

the manufacturing process, virtually

eliminating deflecton under load due to

material stretch

•

They use Simpson Strong-Tie®

Strong-Drive® SDS screws which install

easily and provide reduced fastener slip

•

Using SDS screws results in a greater net

section, when compared to bolts, as no

material is removed

•

The HDU series of holdowns are designed

to replace previous versions of the product such as PHD’S as well

as bolted holdowns. The HDU2, 4 and 5 are direct replacements

for the PHD2, 5 and 6, respectively

HDU Special Features:

•

Pre- deflected body virtually eliminates deflection due to material

stretch

•

Uses SDS screws which install easily, reduce fastener slip, and

provide a greater net section area of the post compared to bolts

•

SDS screws are supplied with the holdowns to ensure proper

fasteners are used

•

No stud bolts to countersink at openings

•

Finish: HDU-Galvanized

SIMPSON STRONG-TIE®

LTT/HTT Tension Ties

•

Tension ties offer a solution for resisting

tension loads that is fastened by nails

•

The entire line of tension ties has been tested

and evaluated to the requirements of AC155

•

The HTT4 and HTT5 are the latest

generation of tension ties. They feature an

optimized nailing pattern which results in bet-

ter

performance with less deflection

•

Designed to meet new code standards, the

HTT4 and HTT5 offer higher loads than their

predecessors

•

The LTTI31 is designed for wood chord open web truss attach-

ments to concrete or masonry walls and may also be installed ver-

tically on a minimum 2x6 stud

•

Finish: Galvanized. May be ordered in HDG; contact Simpson

Strong-Tie

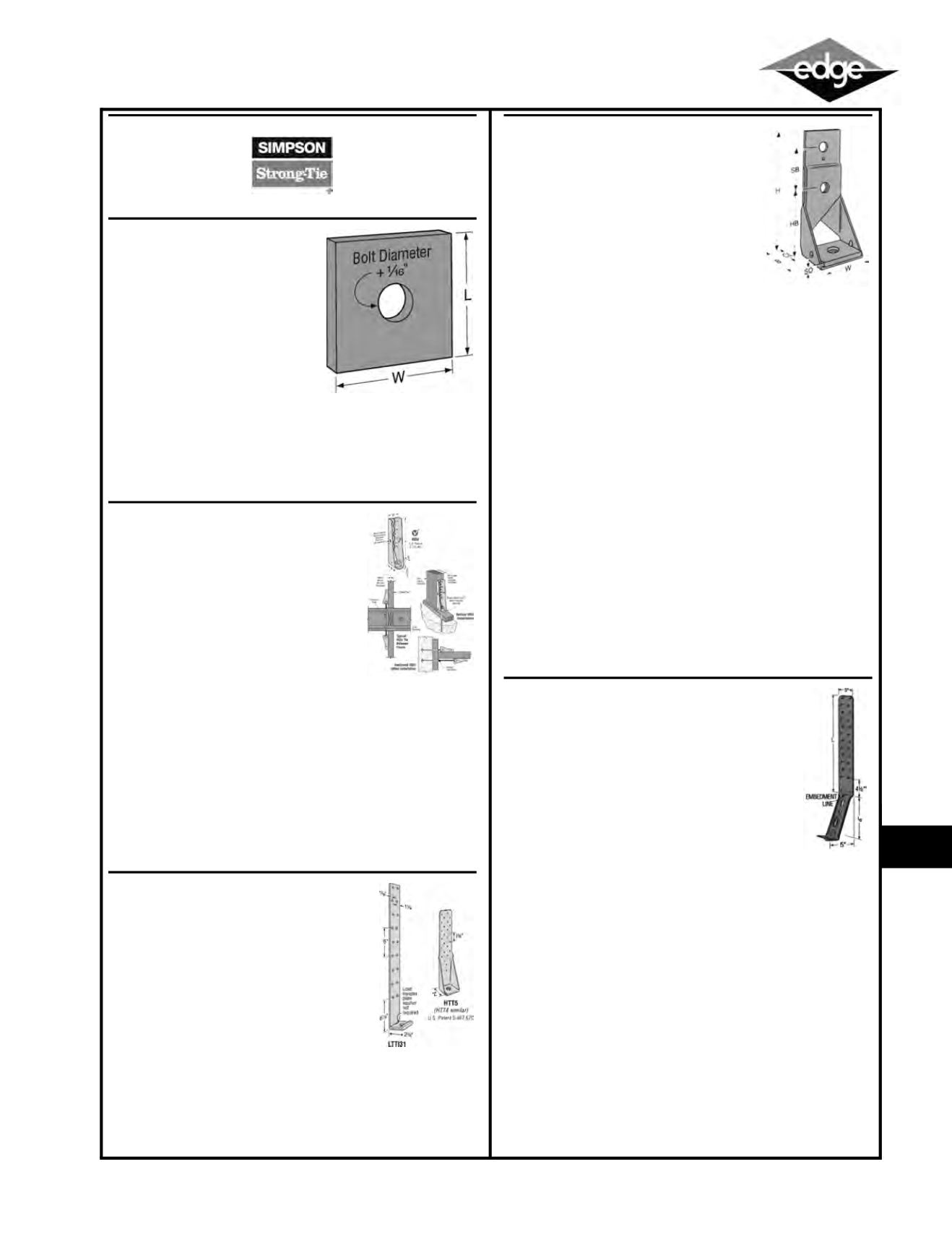

SIMPSON STRONG-TIE®

HD Holdowns

Tension Tie

Holdowns are used to transfer tension loads

between floors, to tie purlins to masonry or

concrete, etc. Use HDAs and HDs for

overturning requirements and other

applications to transfer tension loads. All HDAs

are self-jigging, ensuring code-required

minimum 7 bolt diameter spacing from the end

of the wood member to the center of the first

bolt hole.

HDA Special Features:

•

Single piece non-welded design results in higher capacity

•

Load transfer plate eliminates the need for a seat washer

•

Fewer inspection problems

Finish: Galvanized except HD14A - Simpson gray paint.

1. Allowable loads have been increased 33% for earthquake or wind

loading with no further increase allowed; reduce where other loads

govern.

2. Minimum post size is required to ensure the load carrying capacity

of the critical net section meets the holdown capacity.

3. Minimum post size is required to ensure the load carrying capacity

of the critical net section meets the holdown capacity.

4. HB is the required minimum distance from the end of the stud to

the center of the first stud bolt hole. End distance may be increased

as necessary for installation.

4. The designer must specify anchor bolt type, length and embed-

ment.

5. Lag bolts will not develop the listed loads.

6. Holdowns installed raised off the mudsill have larger deflection

values. Consult Simpson for info.

7. Deflection at highest allowable design load: The deflection of a

holdown measured between the anchor bolt and the strap portion of

the holdown when loaded to the highest allowable load listed. This

movement is strictly due to the holdown deformation under a static

load test conducted on a steel jig.

8. For Hem Fir values request T-HEMFIR.

SIMPSON STRONG-TIE®

STHD Strap-Tie Holdowns

The STHD is an embedded strap tie holdown with

high load capacity and a staggered nail pattern to

help minimize splitting.

•

The strap nailing pattern allows for nailing to the

edges of double 2x’s

•

A slot below the embedment line allows for

increased front to back concrete bond and reduced

spalling

•

Strap nail slots are countersunk to provide a lower

nail head profile

•

Rim joist models accommodate up to a 17" clear

span without any loss of strap nailing

•

Coined edges enhance safe handling

Material: 12 ga.

Finish: Galvanized.

Codes: ICBO 5349.

1.’RJ’ after the model indicates STHDs for rim joist applications

2. STHD14RJ requires 30-16d sinkers, with the (le) load at 133% of

4960 lbs.

3. 10d commons or 12d common nails may be used with no load

reduction.

4. For two pour with 4" slab or less. The STHD14 load at 1/2" edge

2000 psi is 3235. The STHD10 at the same condition is 2035.

5. Allowable loads have been increased 33% and 60% for

earthquake or wind loading with no further increase allowed; reduce

for other load durations according to the code.

6. For Hem-Fir values, request T-Hemfir.

7. Strap may be bent one full cycle.

Min Stem Wall: 8