Sales

Rental

Repair

Lindapter-Structural Fastening

Boise, ID 208-377-0158

Eugene, OR 541-342-3641

Idaho Falls, ID 208-522-7082

Medford, OR 541-779-0187

543

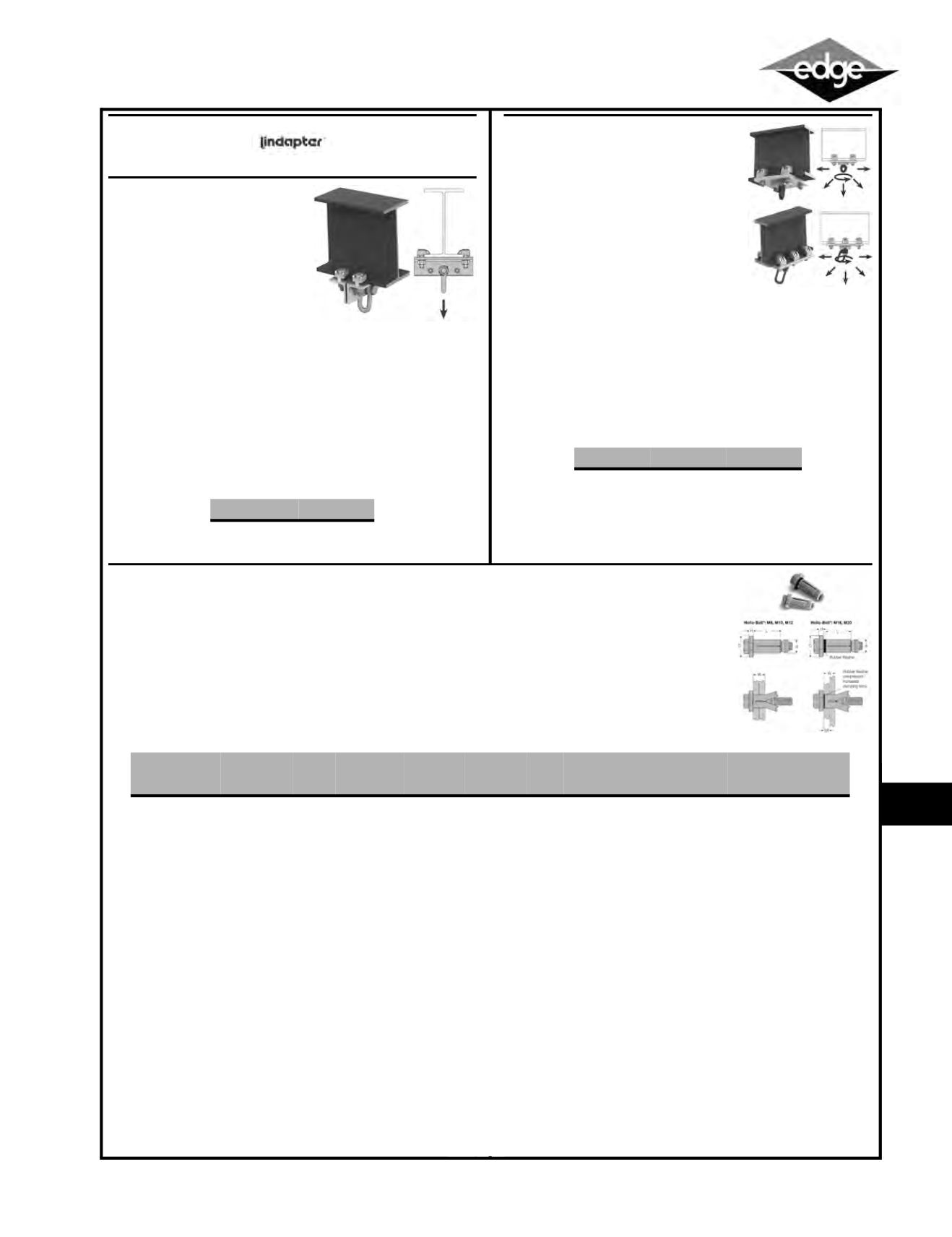

LINDAPTER®

TYPE SC -

Shackle Clamp

Steel Clamp

•

The Lindapter 4 bolt Shackle

Clamp is a custom made

assembly which can be

manufactured to suit any width

and thickness of supporting

section

•

Suitable for vertical lifts where the angle tolerance is less than 10

degrees

•

All loads subject to suitability of supporting section

•

Clamps: Malleable iron

•

Angles: Mild steel

•

D Shackle: Forged steel

•

Corrosion protection as required

•

Contact Edge for detailed specs and design data

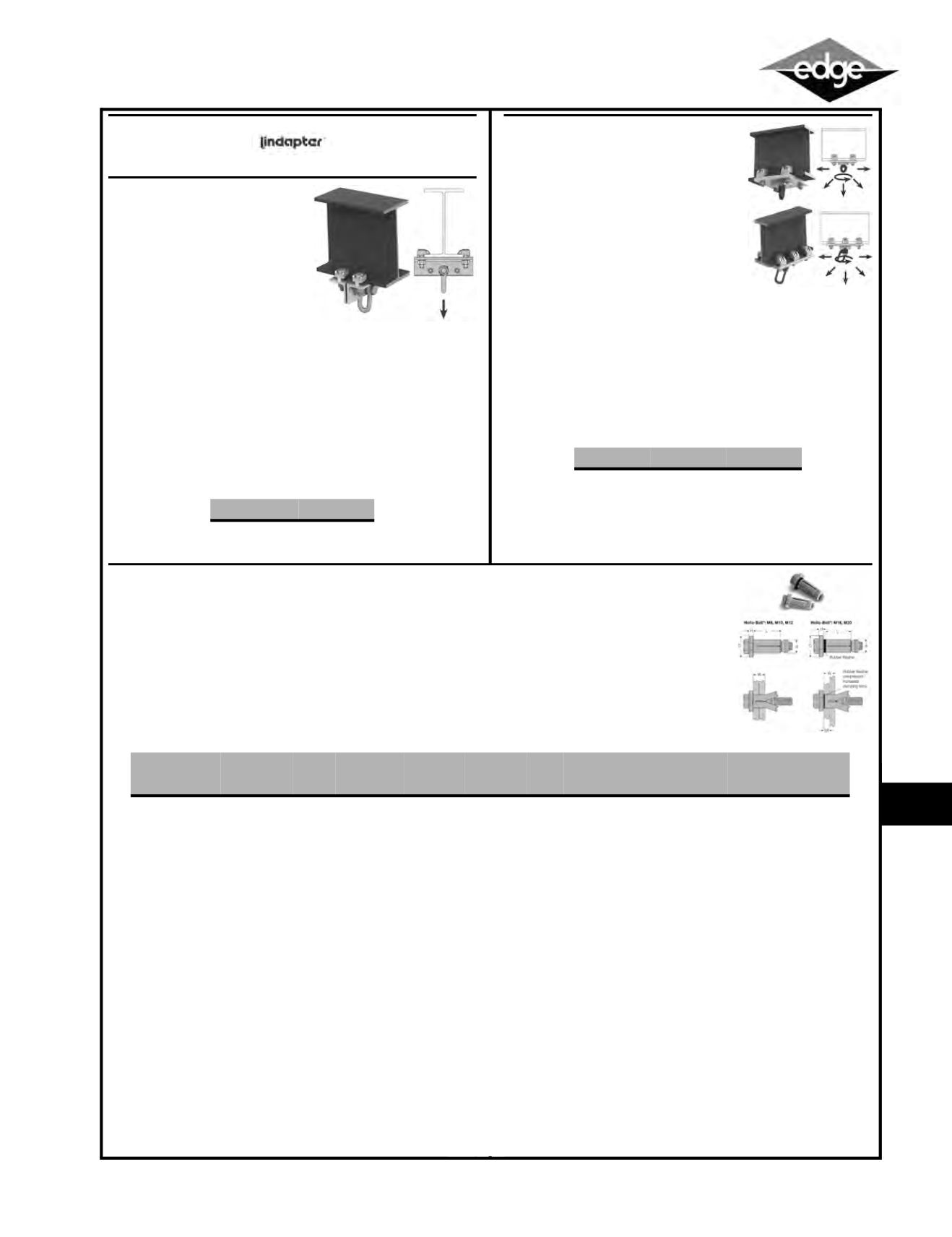

LINDAPTER®

TYPE LP4/LP6 -

Lifting Points

Steel Clamp

•

LP4: Lifting Point with 4 bolts

•

LP6: Lifting Point with 6 Bolts

•

Custom designed for multiple applica-

tions with vertical load, loads at an angle

of 0-90° and rotation of up to 360°

•

All loads subject to suitability of support-

ing section

•

Clamps: SG iron

•

Plate: Mild steel

•

Lifting Eye: Forged steel

•

Corrosion Protection as required

•

Contact Edge for detailed specs and design data

LINDAPTER®

TYPE HB-Hollo-Bolt®

Hollow Section (HSS) Connection

•

Suitable for steel hollow sections, tubes and where access is available from one side only

•

For corrosion protection, the Hollo-Bolt® comes with additional JS500 protection as standard

•

Steel, bright zinc plated plus JS500 steel, hot dip galvanized or stainless steel grade 316

•

Sizes 5/8" and 3/4" have a patented collapse mechanism for optimized clamping force

•

Standard head style is Hex Head. Also available in Flush Fit, Countersunk and Button Head Security

•

Contact Edge for detailed specs and design data

Item #

Loading

LDTYPE SC Up To 13kip

Item # Description Loading

LDLP4

4 Bolts Up To 10 kip

LDLP6

6 Bolts Up To 22.5

kip

Item #

Size Metric

(US Equiv.)

Z

Bolt

Lengt

h

Clamping

Thickness

W

Outer

Ply¼ min

t

Sleeve

Length

(in.)

Oute

r Ø L

Torque

(ft.lb.)

Safe Working Loads

(5:1 Factor Of Safety)

Tensile (lbs.)

Safe Working Loads

(5:1 Factor Of Safety)

Single Shear (lbs.)

LDLHBM08 #1 M8 (

⁵⁄₁₆

”)

2”

¹⁄₈

”-

⁷⁄₈

”

1

³⁄₁₆

”

⁹⁄₁₆

”

17

899

1,124

LDLHBM08 #2 M8 (

⁵⁄₁₆

”)

2

³⁄₄

”

⁷⁄₈

”-1

⁵⁄₈

”

1

⁵⁄₁₆

”

⁹⁄₁₆

”

17

899

1,124

LDLHBM08 #3 M8 (

⁵⁄₁₆

”)

3

⁵⁄₈

”

1

⁵⁄₈

”-2

³⁄₈

”

2

¹¹⁄₁₆

”

⁹⁄₁₆

”

17

899

1,124

LDLHBM10 #1 M10 (

³⁄₈

”)

2

¹⁄₄

”

¹⁄₈

”-

⁷⁄₈

”

1

³⁄₁₆

”

³⁄₄

”

33

1,910

2,248

LDLHBM10 #2 M10 (

³⁄₈

”)

3”

⁷⁄₈

”-1

⁵⁄₈

”

1

⁷⁄₈

”

³⁄₄

”

33

1,910

2,248

LDLHBM10 #3 M10 (

³⁄₈

”)

3

⁵⁄₈

”

1

⁵⁄₈

”-2

³⁄₈

”

2

⁵⁄₈

”

³⁄₄

”

33

1,910

2,248

LDLHMB12 #1 M12 (

¹⁄₂

”)

2

³⁄₈

”

¹⁄₈

”-1”

1

³⁄₈

”

¹³⁄₁₆

”

59

2,360

3,372

LDLHMB12 #2 M12 (

¹⁄₂

”)

3

⁵⁄₈

”

1”-1

¹³⁄₁₆

”

2

¹⁄₄

”

¹³⁄₁₆

”

59

2,360

3,372

LDLHMB12 #3 M12 (

¹⁄₂

”)

4

¹⁄₄

”

1

¹³⁄₁₆

”-2

³⁄₄

”

3

¹⁄₈

”

¹³⁄₁₆

”

59

2,360

3,372

LDLHBM16 #1 M16 (

⁵⁄₈

”)

3”

¹⁄₂

”-1

¹⁄₈

”

⁵⁄₁₆

”

1

⁵⁄₈

”

1

¹⁄₁₆

”

140

4,720

6,744

LDLHBM16 #2 M16 (

⁵⁄₈

”)

4”

1

¹⁄₈

”-2”

⁵⁄₁₆

”

2

¹⁄₂

”

1

¹⁄₁₆

”

140

4,720

6,744

LDLHBM16 #3 M16 (

⁵⁄₈

”)

4

³⁄₄

”

2”-2

¹³⁄₁₆

”

⁵⁄₁₆

”

3

⁵⁄₁₆

”

1

¹⁄₁₆

”

140

4,720

6,744

LDLHBM20 #1 M20 (

³⁄₄

”)

3

⁵⁄₈

”

¹⁄₂

”-1

⁵⁄₁₆

”

⁵⁄₁₆

”

1

¹⁵⁄₁₆

”

1

⁵⁄₁₆

”

221

7,868

8,992

LDLHBM20 #2 M20 (

³⁄₄

”)

4

³⁄₄

”

1

⁵⁄₁₆

-2

³⁄₈

”

⁵⁄₁₆

”

3”

1

⁵⁄₁₆

”

221

7,868

8,992

LDLHBM20 #3 M20 (

³⁄₄

”)

5

⁷⁄₈

”

2

³⁄₈

”-3

³⁄₈

”

⁵⁄₁₆

”

4”

1

⁵⁄₁₆

”

221

7,868

8,992